Maintenance of Way (MOW) Equipment tailored to your needs

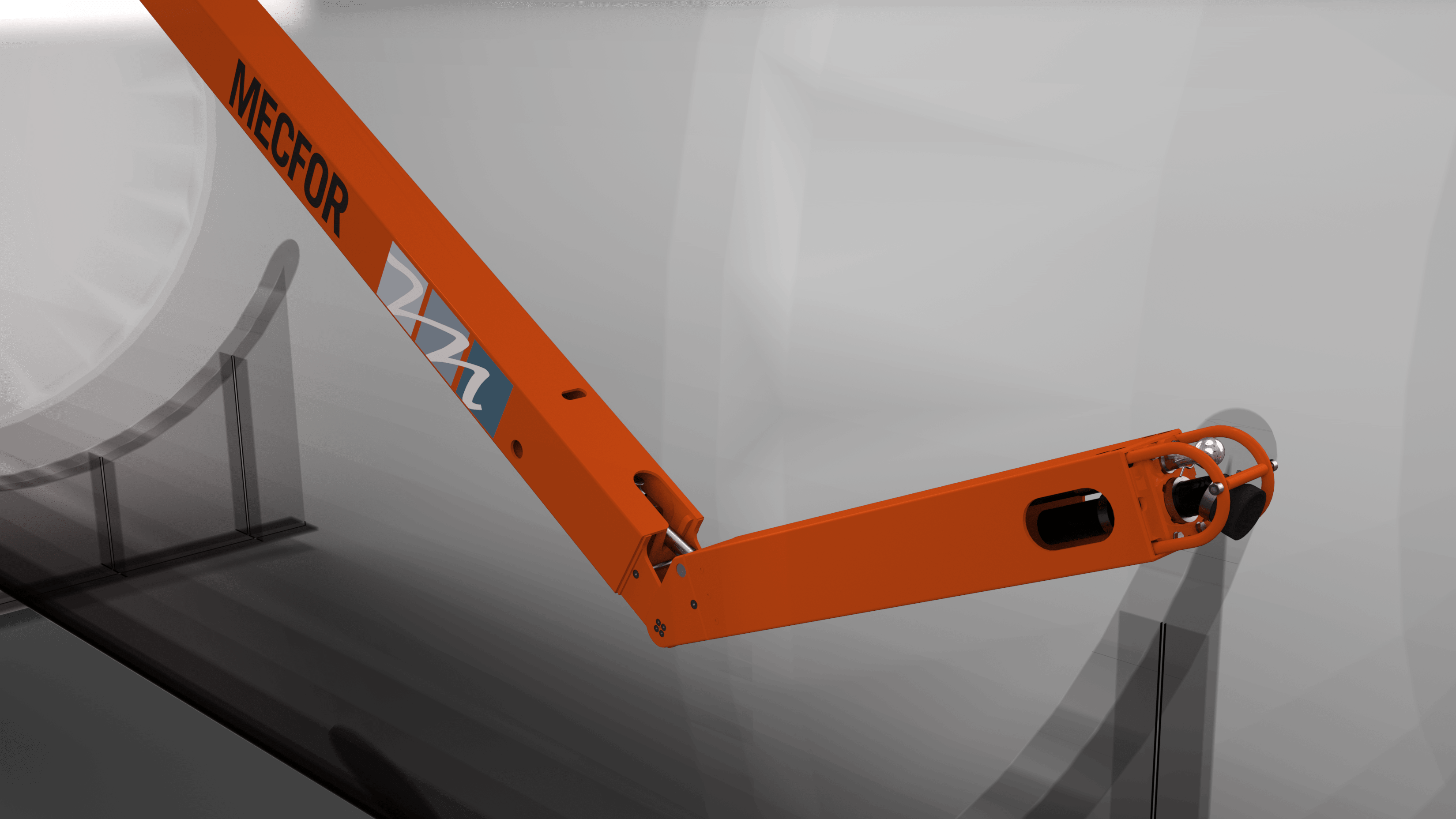

Under MECFOR brand, EPIQ Machinery offers rail maintenance equipment for transits, railroads and contractors.

When it comes time to think of rail maintenance equipment for changing climates and harsh working environments, MECFOR comes to mind. Despite the extreme operating conditions, MECFOR equipment is sturdy, ergonomic and among the most reliable in the industry.

The company benefits from a creative and experienced team always ready to outdo the needs of its customers. From design to manufacturing, including refurbishing and scheduled maintenance, MECFOR presents a solid know-how in the railway sector.

MECFOR mission is to manufacture innovative and effective solutions for the railroads, but also subways and trams as well as branched industrial sites. With our passion for challenges, we will also take on Special projects.

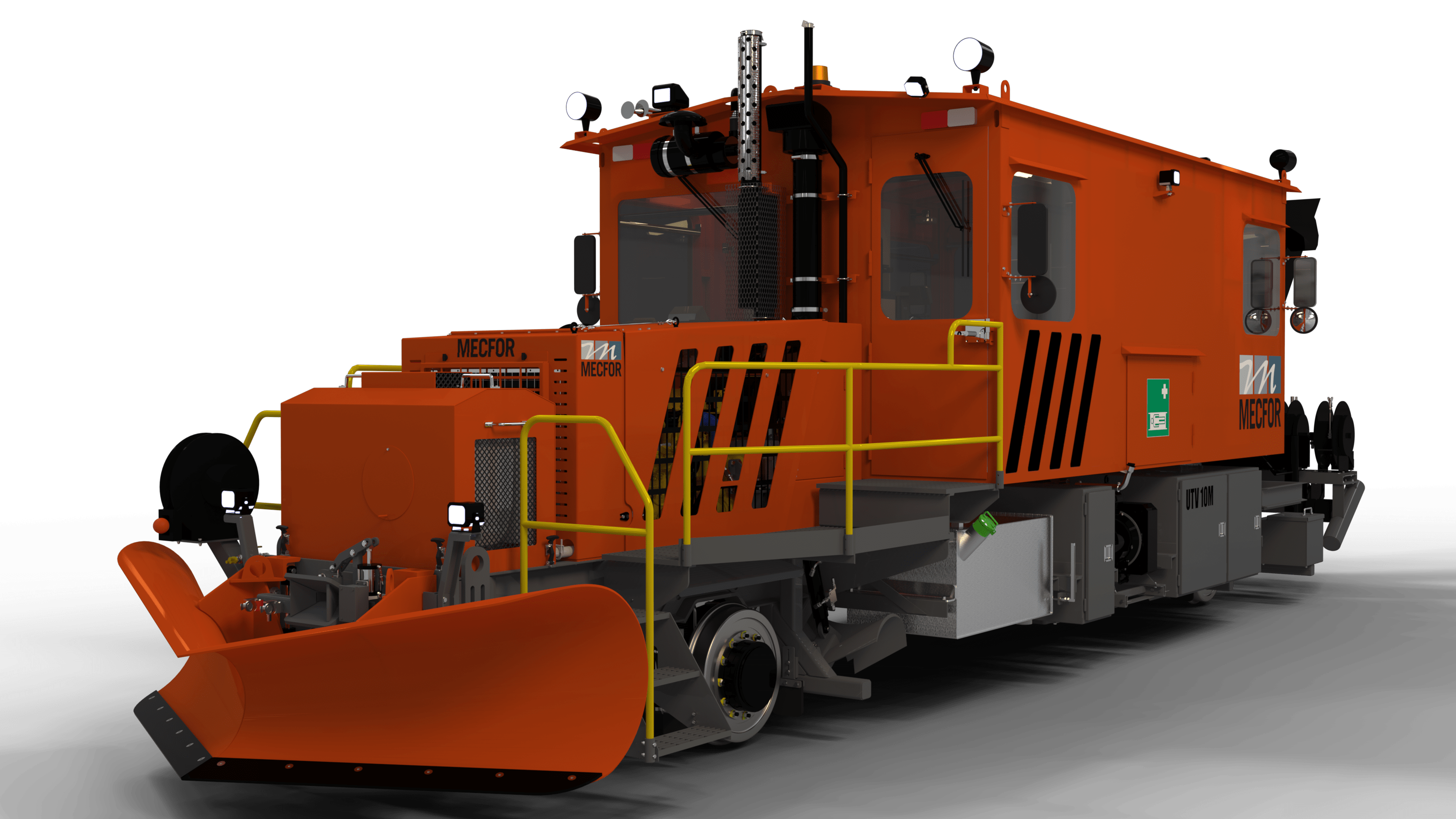

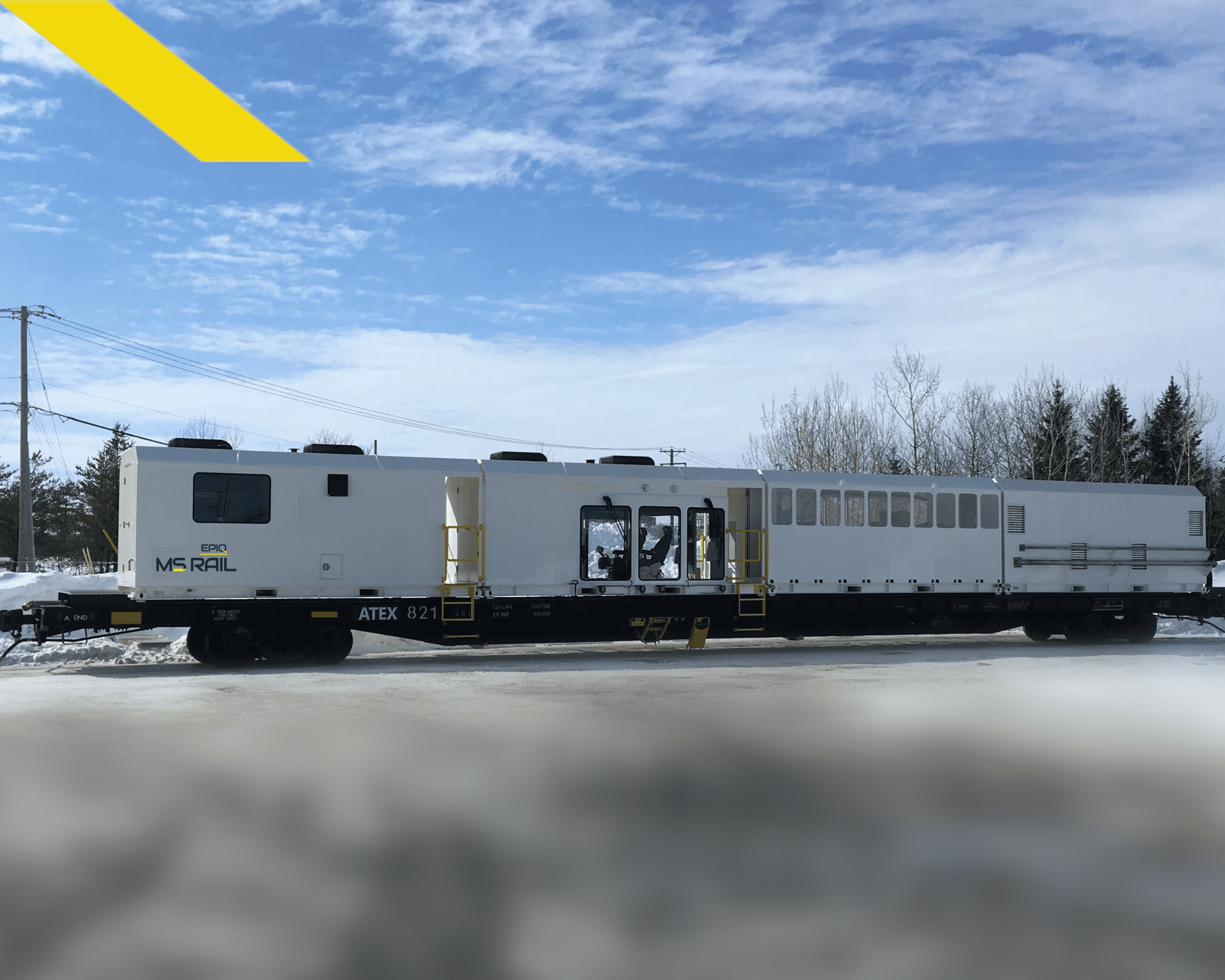

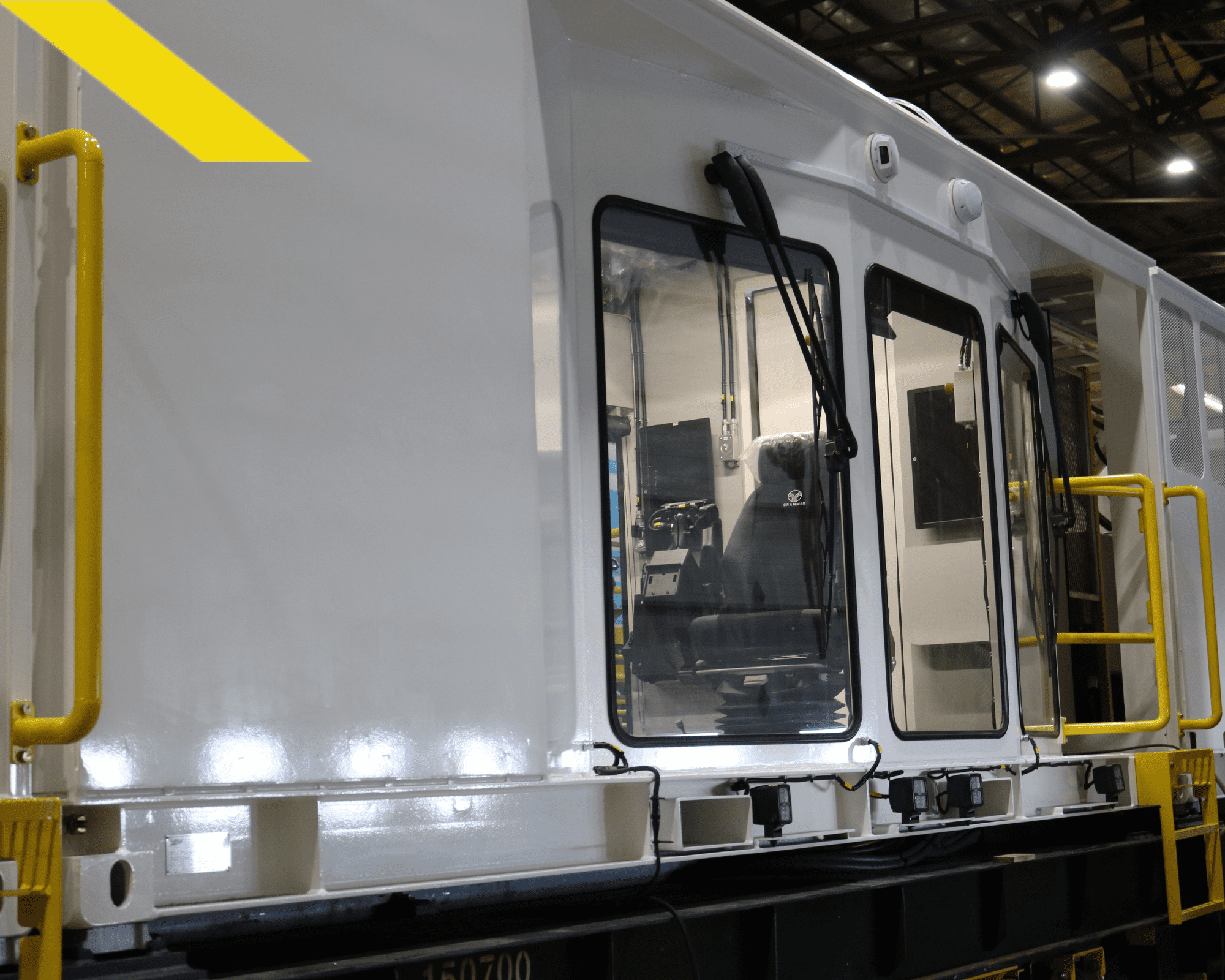

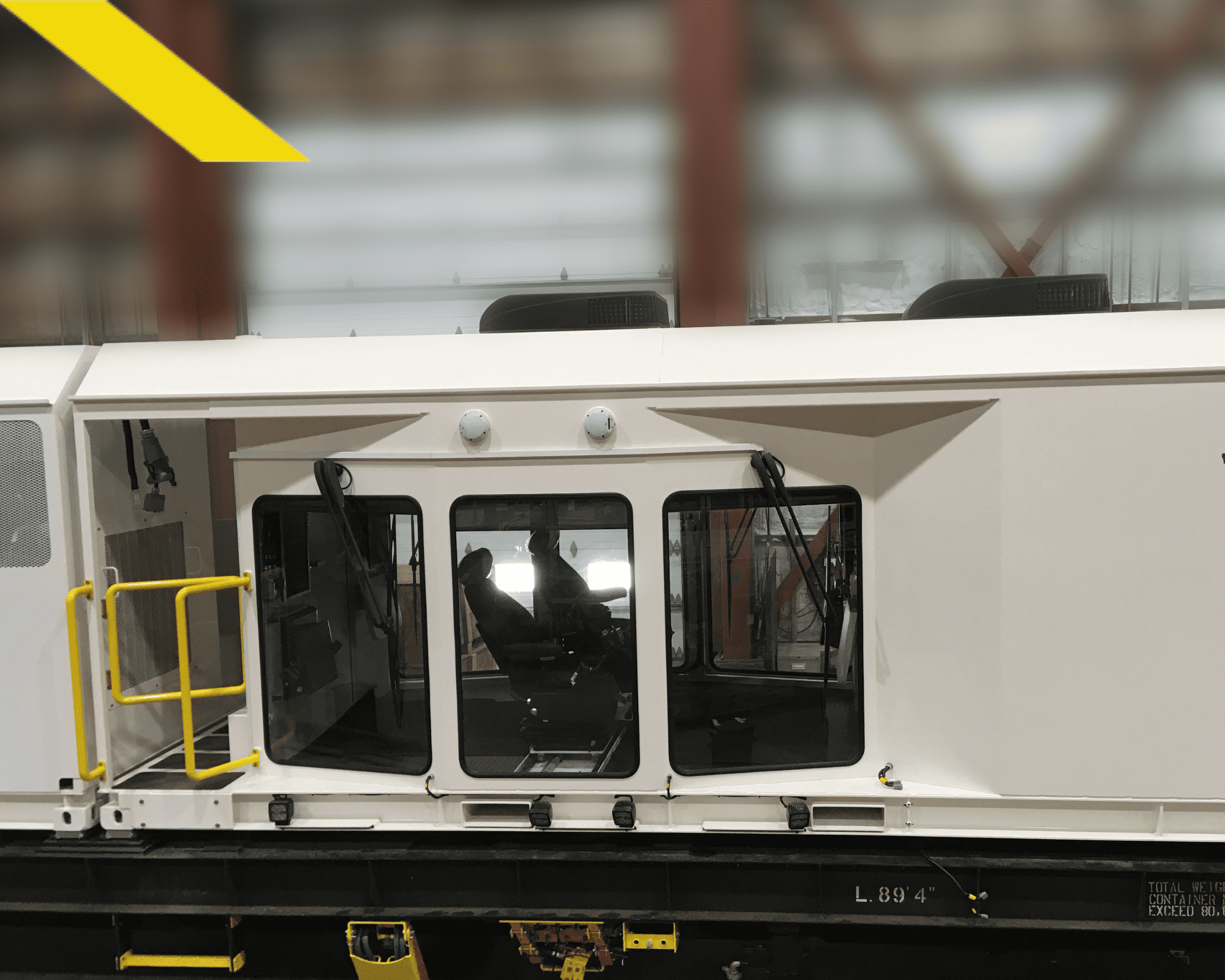

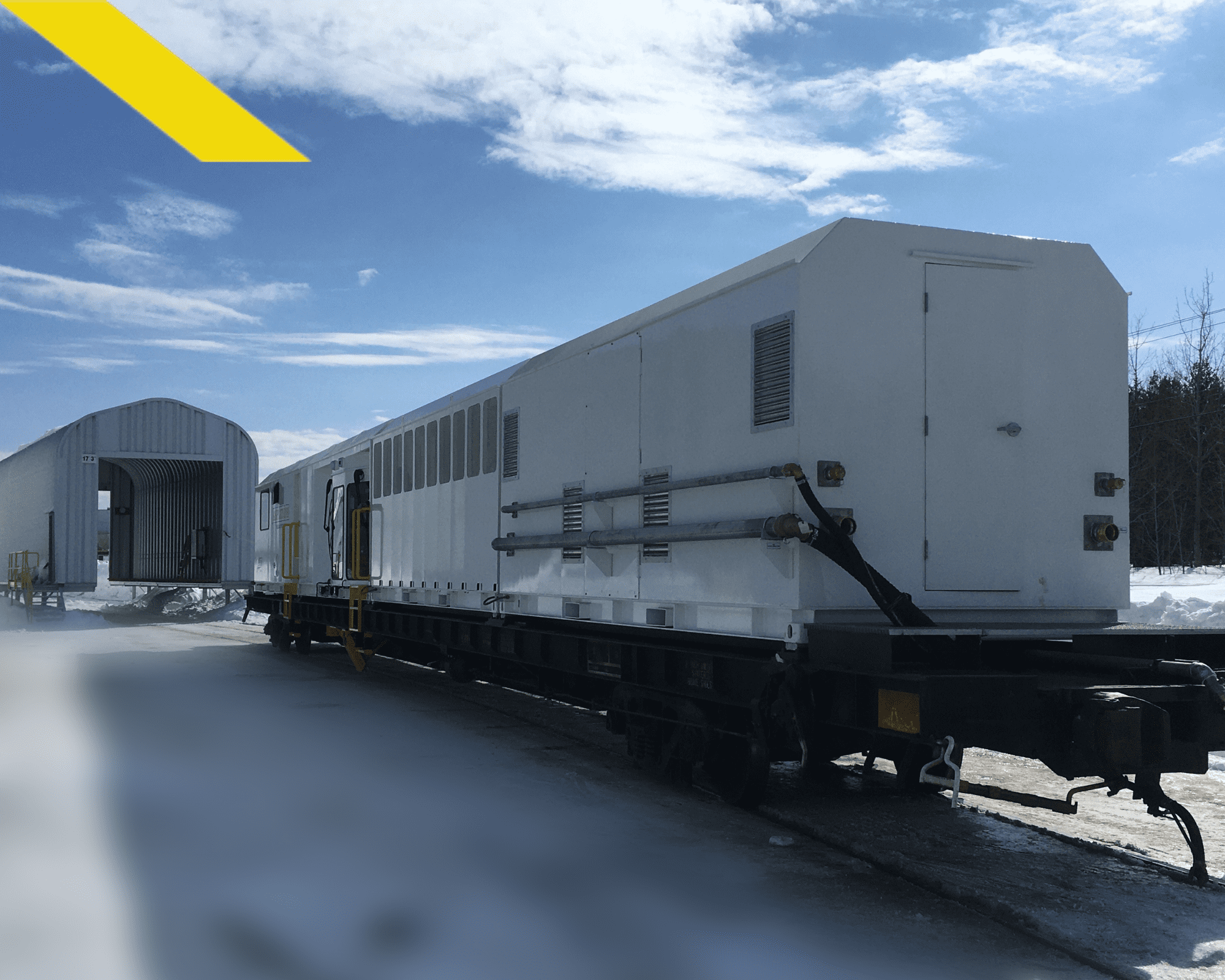

Rail Maintenance Vehicle

Rail changer | utility rail vehicle, model UTV

MECFOR Rail Changer, model UTV, offers high safety standards and level of comfort for your crew. This multipurpose rail equipment comes handy when rail maintenance is done on long distance in remote regions.

MECFOR Rail Changer, UTV model, comes with Standard functionalities:

- Hydraulic hood

- Hydrostatic transmission

- External fail-safe hydraulic brake

- Two (2) powered axles

- 180-degrees rotation system

- CAN control system

- Two command seats

- Lunchroom

- Numerous locks for increased safety

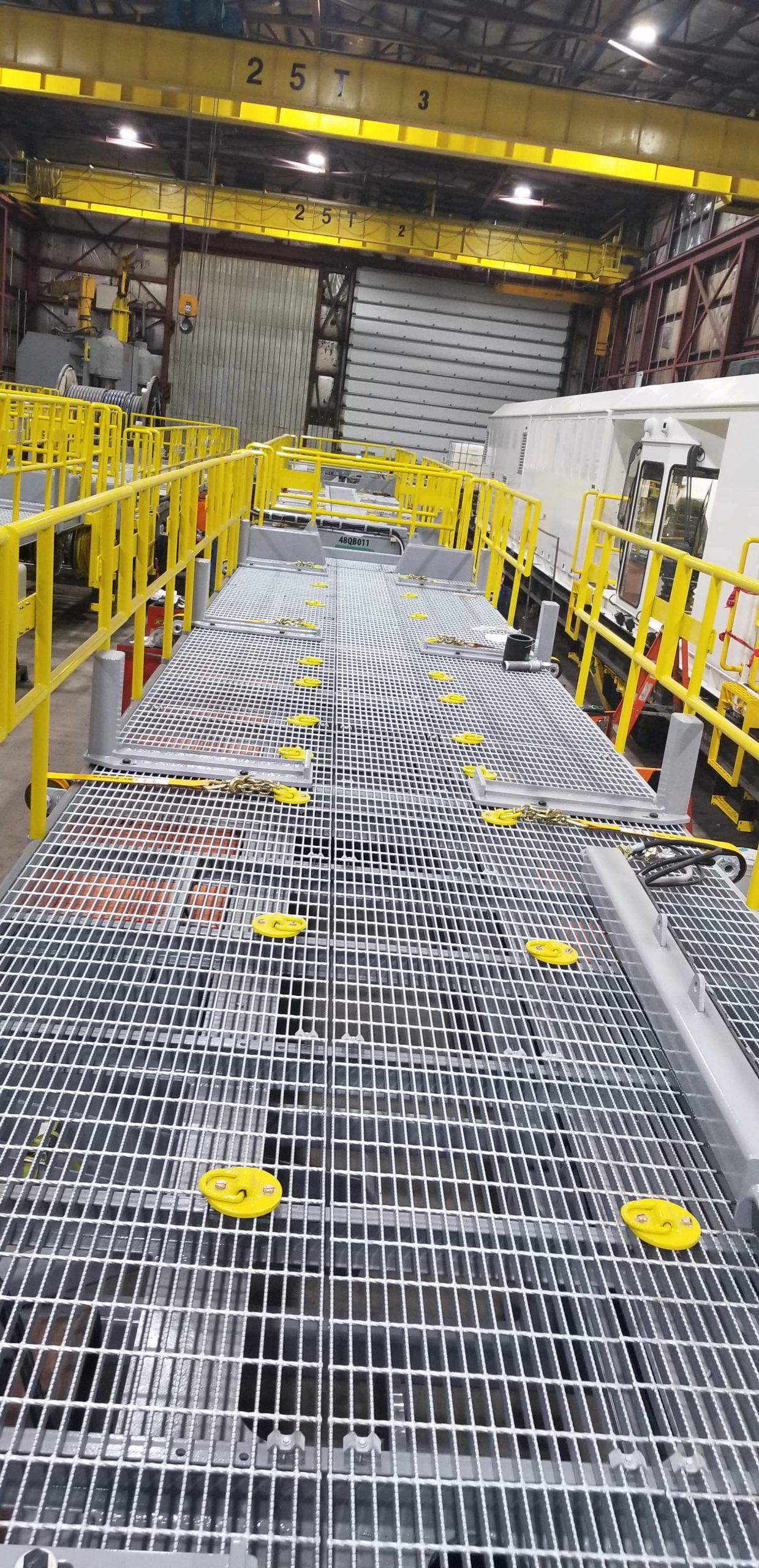

Lorry with crane|material handling

Lorry trailer is used to form a convoy pulled by a towing vehicle.

- Articulated boom loading crane

- Hydraulic power unit on the crane driven by an electric motor

- Floor load capacity: 6,800 kg

- Speed: 40 km / h

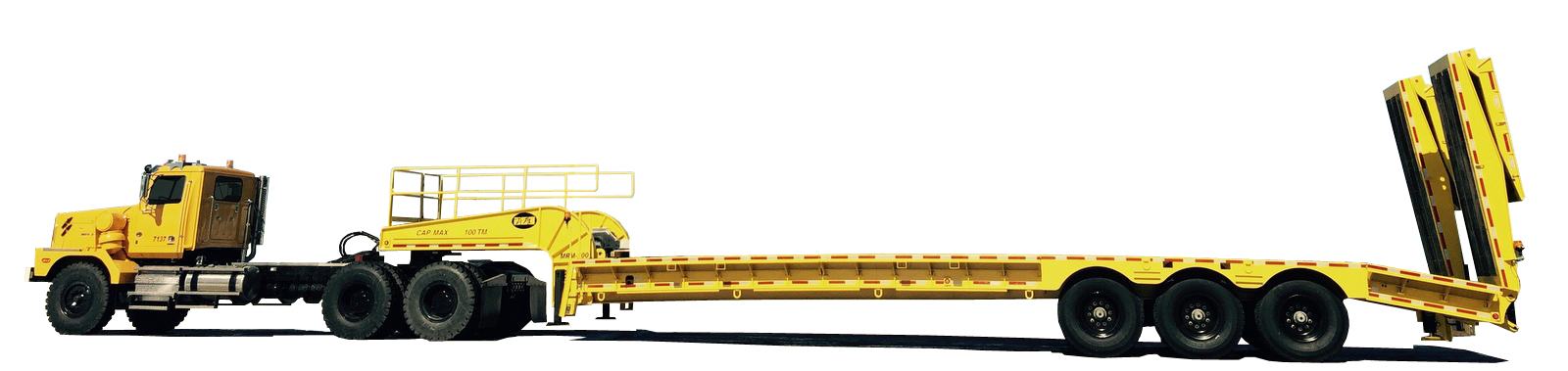

Boggie trailer

Our boggie trailers feature :

- Generator

- Spacious toolboxes

- 40-foot cargo space

- Access ladder to the bridge

- Removable bodyguards

- Anti-derailment system

- Pressurized air

- Disc brakes

- Locomotive light

Modular road/rail equipment

- Vegetation control module

- Catenary maintenance module

- Crane and beam module

- Water tank module

- Defrost module

- Other modules that can be adapted (e.g.: abrasives and high-pressure cleaning)

Welding truck

- Crane

- Storage boxes

- Pressurized air

- Winch

- Welder & accessories

Vegetation control train

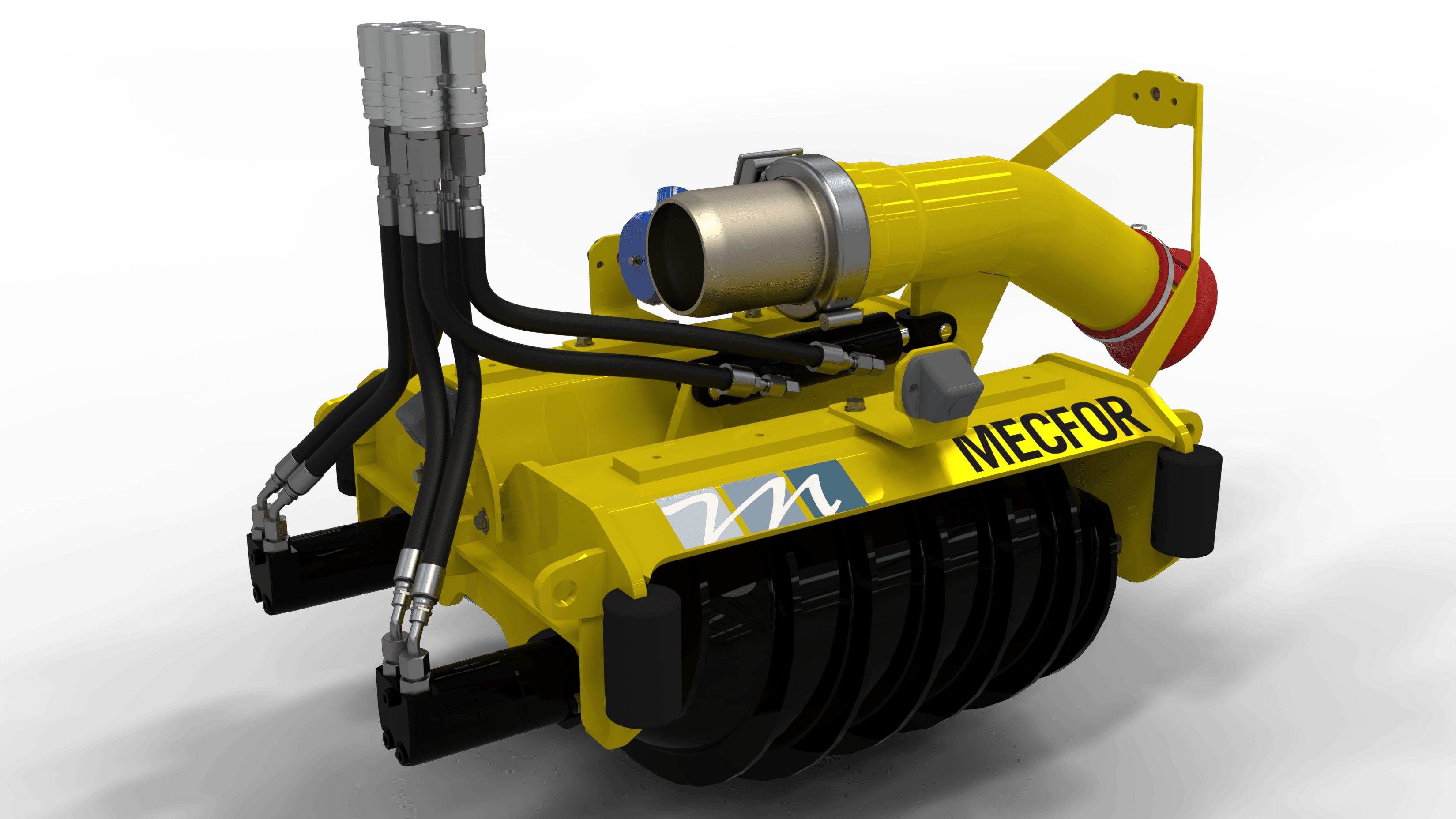

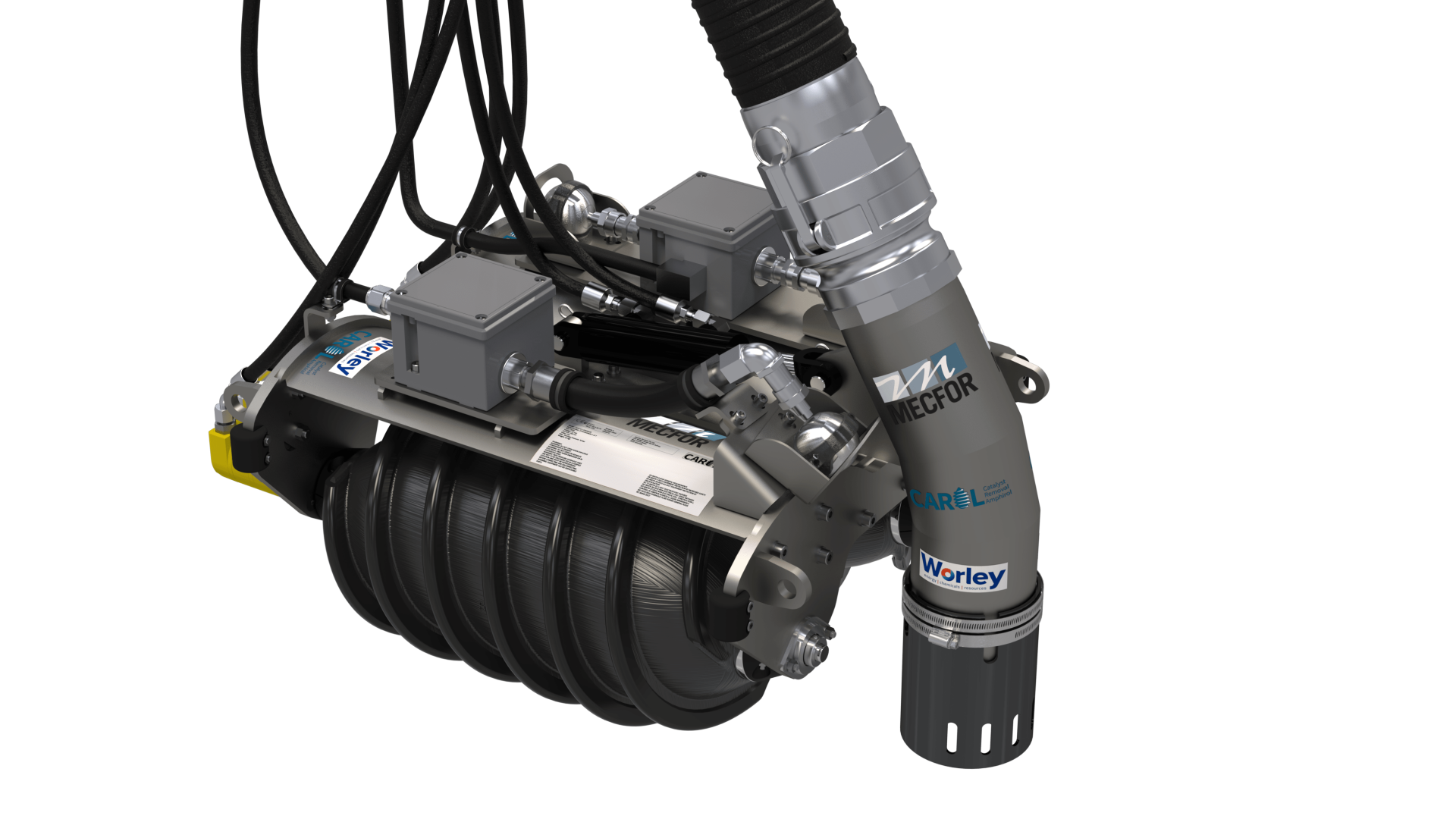

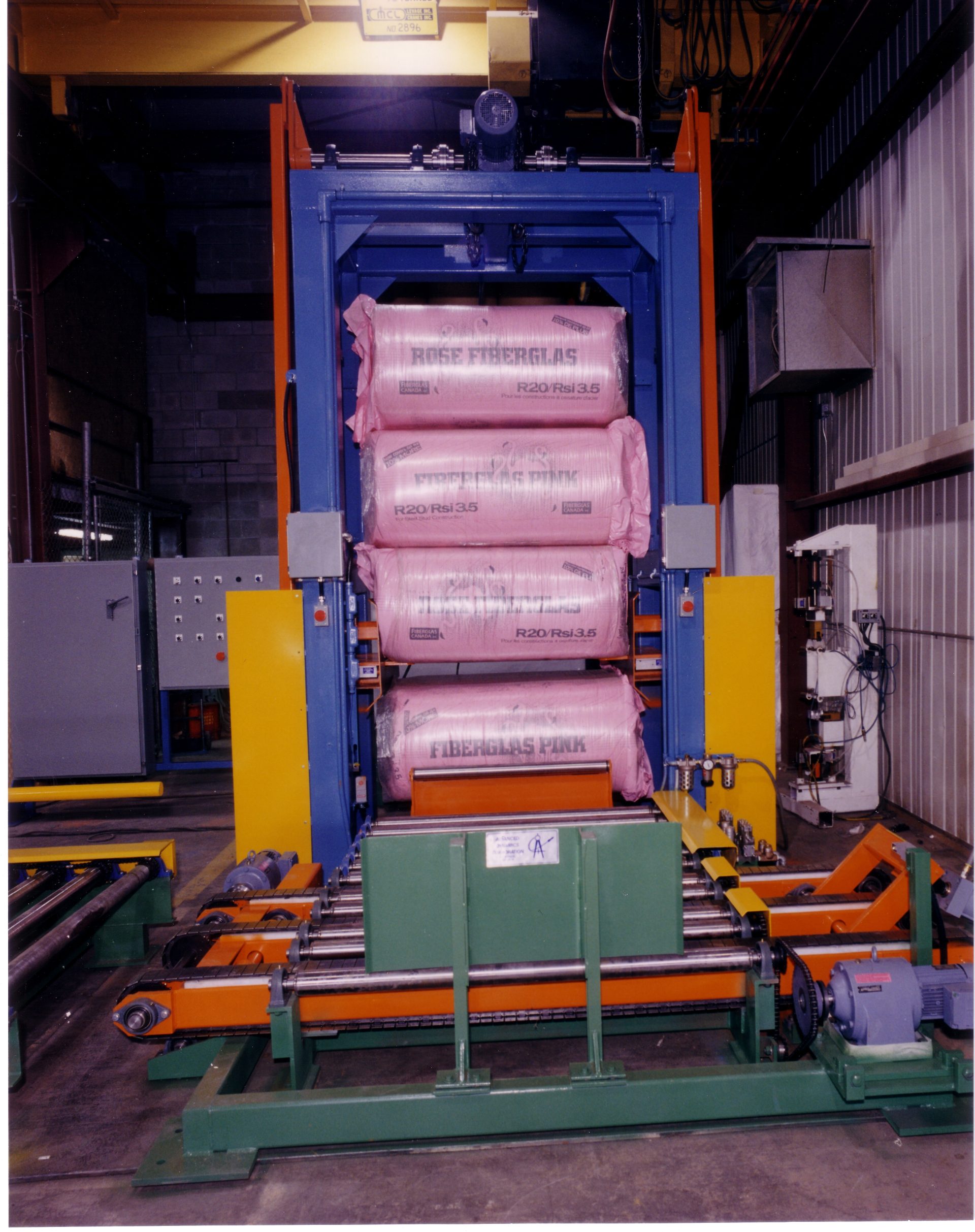

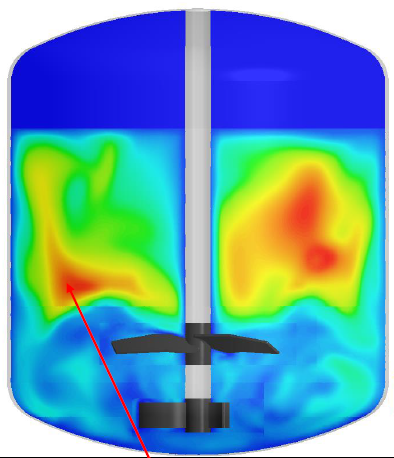

MECFOR Vegetation Control Unit is loaded with high-level technologies for greater control over chemicals used at this task, making the equipment environmentally and community friendly.

This new piece of equipment helps to better controling vegetation and weeds offering a unique spraying system. Available in full version of 4 modules or according to the needs of the service operator for hi-rail trucks.

Main characteristics :

- Spraying modules for maximum accuracy on vegetation

- High density cameras and lights

- Wastewater disposal

- Easy connection between modules

- Comfort and ergonomics – control station with camera, joystick, screens: everything within reach of the operator; without forgetting the vision thanks to multiple windows

- Functional storage, ventilated toilet and shower, dining area

- Enough power and energy for long trips

- Easy controls and functional accesses

- Perfectly balance and safe dosage management

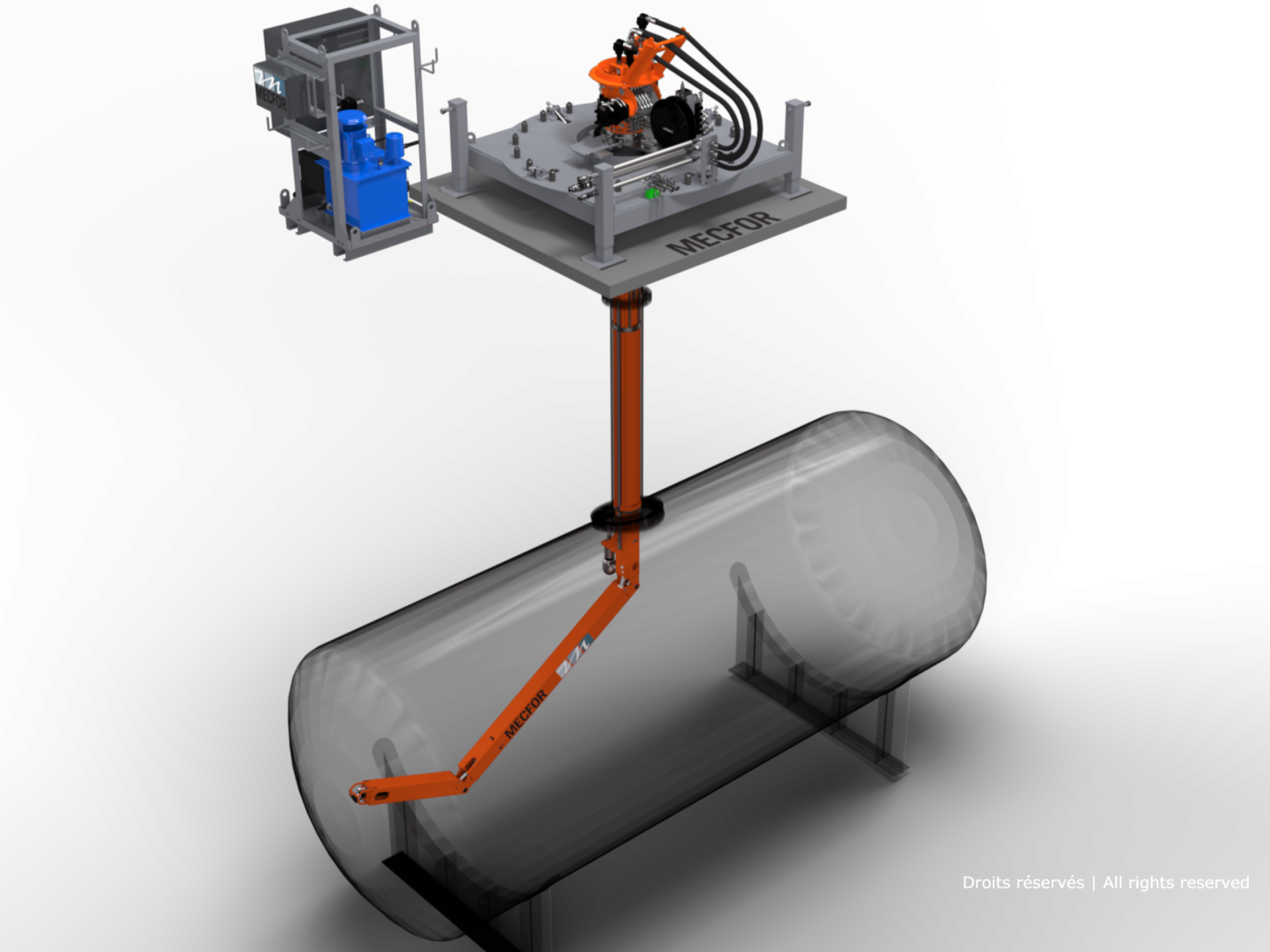

Special Projects

Your needed equipment is no where to found! Call EPIQ team for rail maintenance equipment that offers high level of performance, both operational and financial.

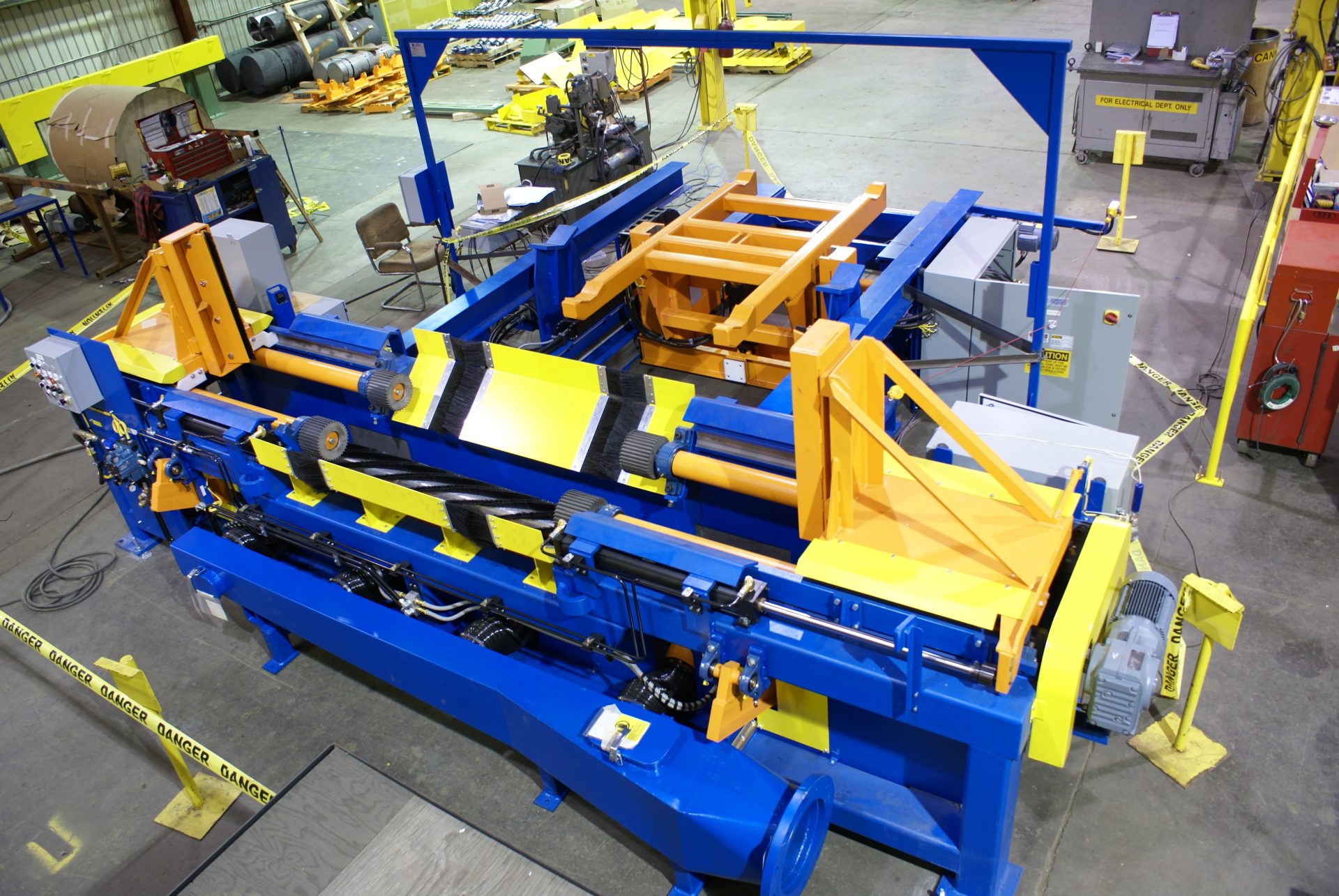

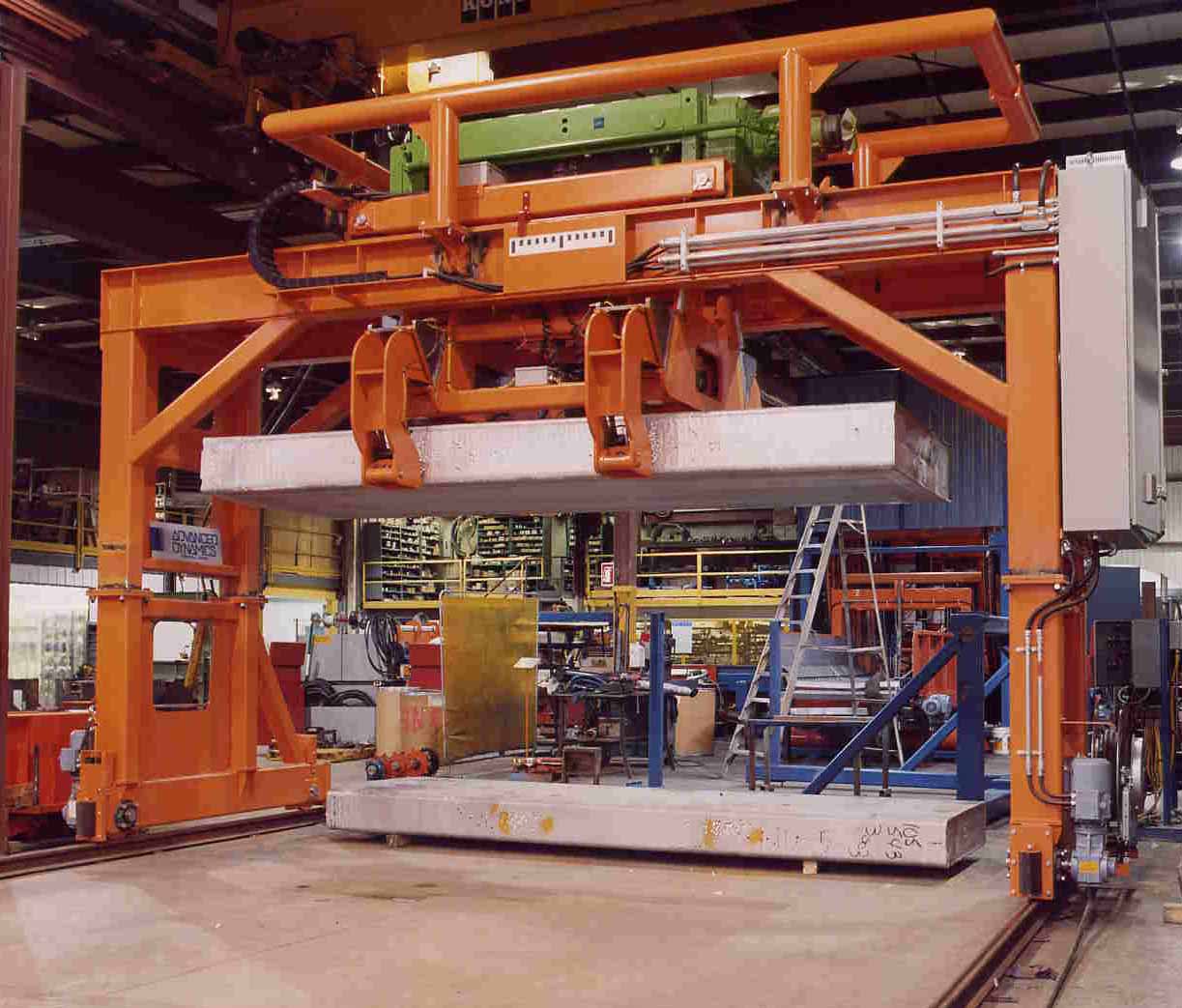

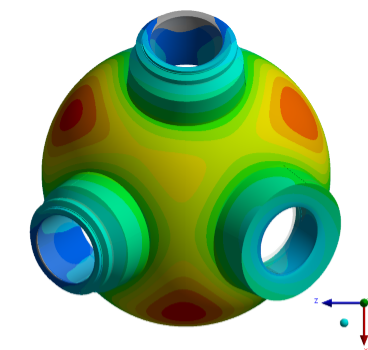

Train wheel manipulator and Elevator plateform

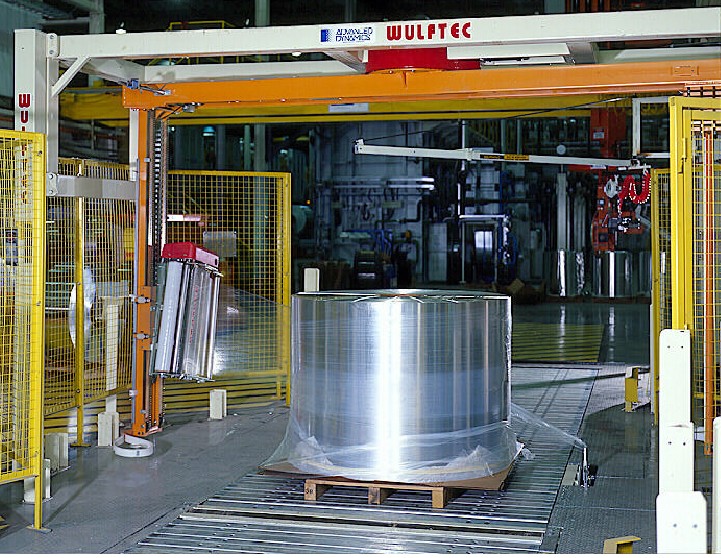

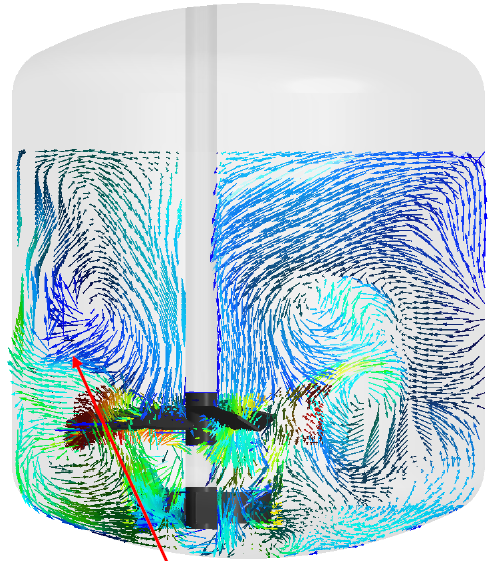

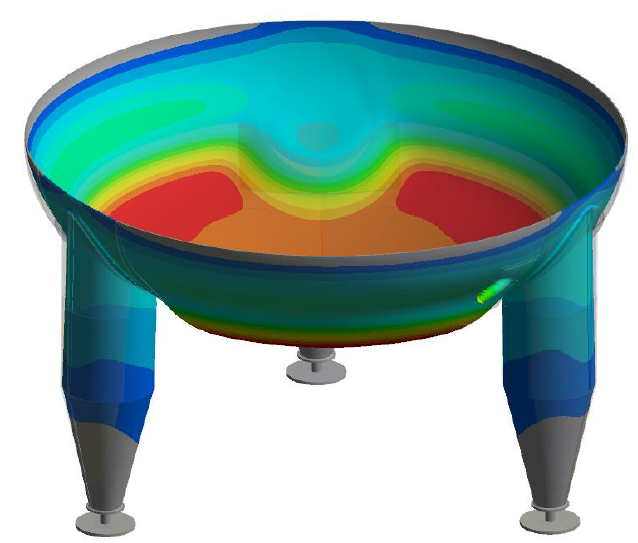

Locomotive Turntable

Our client was looking to rejuvenate his turntable which had been installed and put into operation in the early 1920s. We had the mandate to design, manufacture and supervise the installation of a turntable respecting the new standards and the new operational reality of the client, and this, inside the imprint of the original table.

The project was carried out in synergy with several stakeholders. Frequent communications during the project made it possible to quickly resolve the limiting issues identified by each of the stakeholders. Thanks to listening and the sharing of expertise between everyone, we have delivered equipment of which we are proud.

The turntable is now silent, easier to operate and maintain. It stands our rigorous winters with heavy accumulations of snow! The turntable project had all the characteristics that drive our passion for challenges.

Check the video showcasing the turntable project, click here.

We can take on your toughest challenges. Our goal? Increase your productivity. 5 decades of successful business speak for themselves.

We can take on your toughest challenges. Our goal? Increase your productivity. 5 decades of successful business speak for themselves.