We are a company that provides adapted equipment solutions and optimizes heavy industrial handling operations by improving processes from the carbon sector, the potroom up to the casthouse.

Innovative Equipment

Our equipment meets modern criteria. During the design process, EPIQ Machinery engineering team integrates various components that make it easier to track equipment status, maintenance, and even standardize how operations are done. On the lookout for innovations and technical improvements available through our network of elite suppliers, EPIQ designs and manufactures state-of-the-art equipment, including Rodding Shop equipment, anode and molten metal crucible haulers, Casthouse Specialized vehicles, with an unmatched operational lifespan in the industry.

Increased Yields

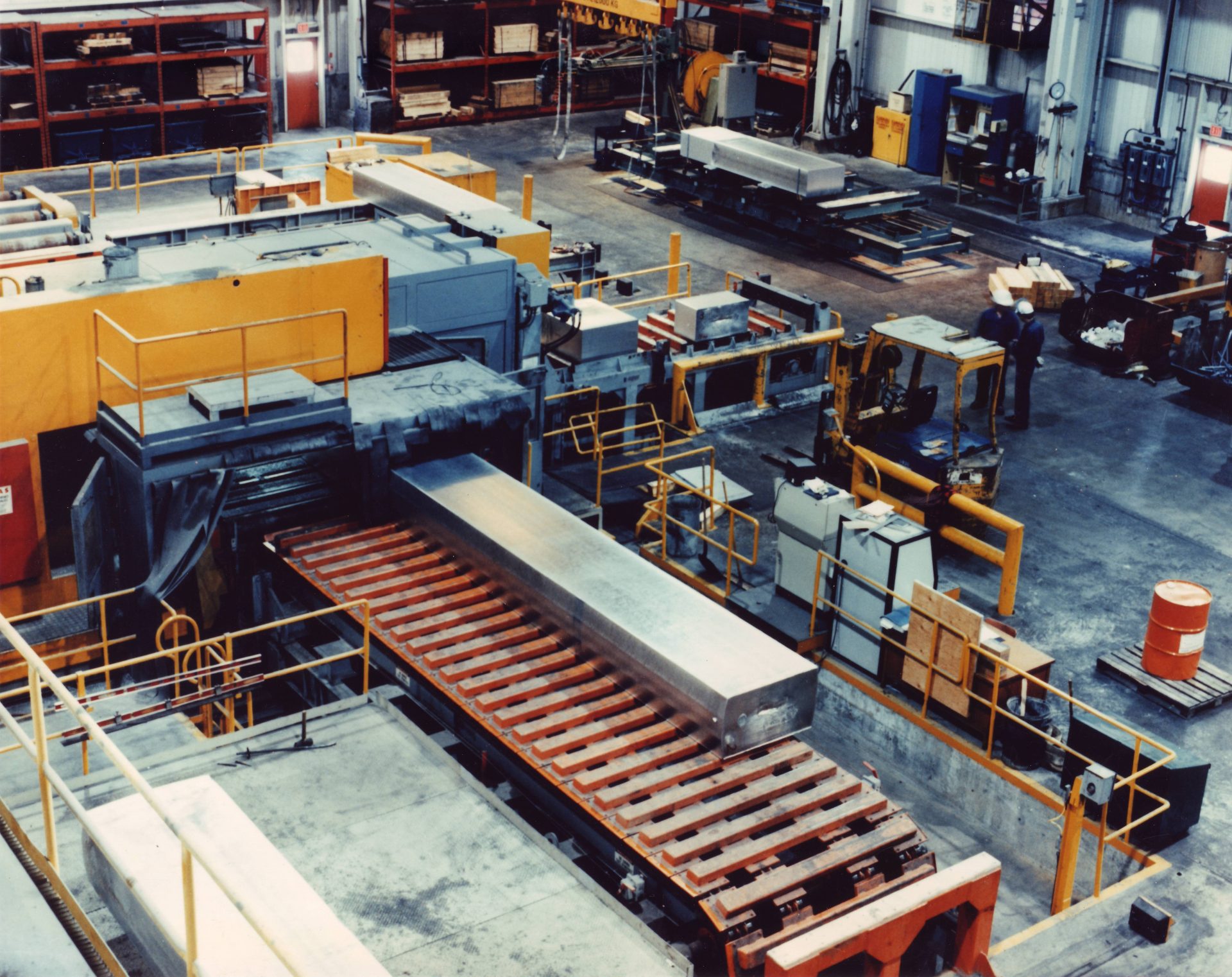

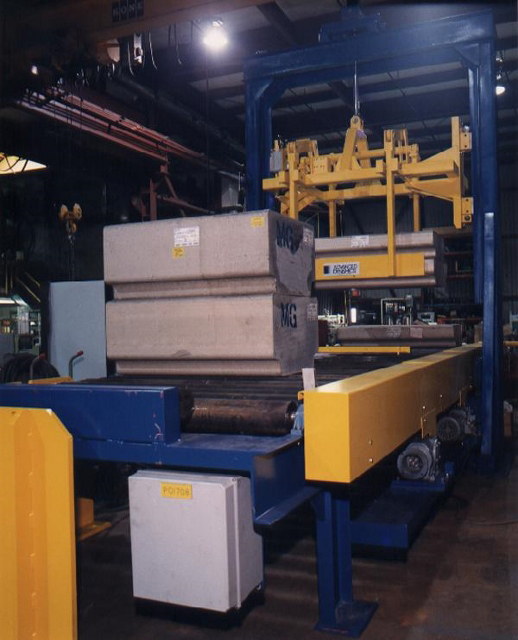

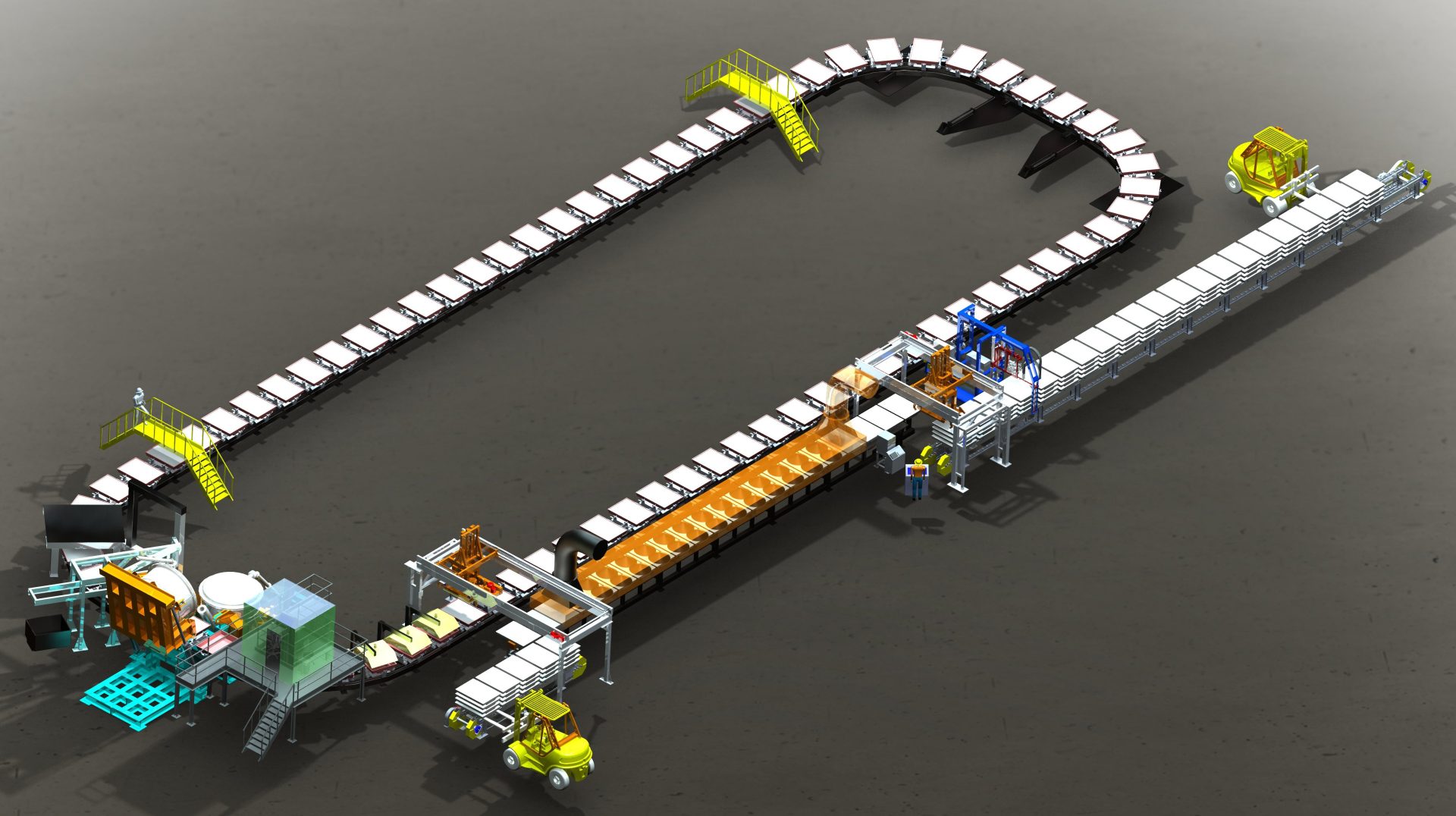

EPIQ Machinery engineers and manufactures mission critical material handling, processing systems and mobile equipment for world leading primary aluminum and secondary smelters worldwide. Our heavy-duty material handling systems for aluminium casthouse and smelters, as well as our anode handling and cleaning systems, are designed to provide exceptional performance.

Our operations, engineering, and manufacturing teams have the experience and expertise to guarantee the best returns in the industry. Once the equipment is delivered and put into operation, you can rely on the after-sales service department. Qualified technicians will provide you with high-level technical support to maintain maximum productivity and minimize unplanned downtime.

Proven Technology; Proven Results.

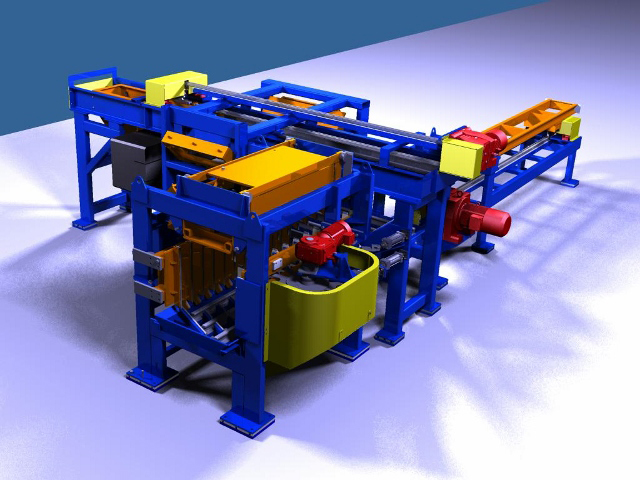

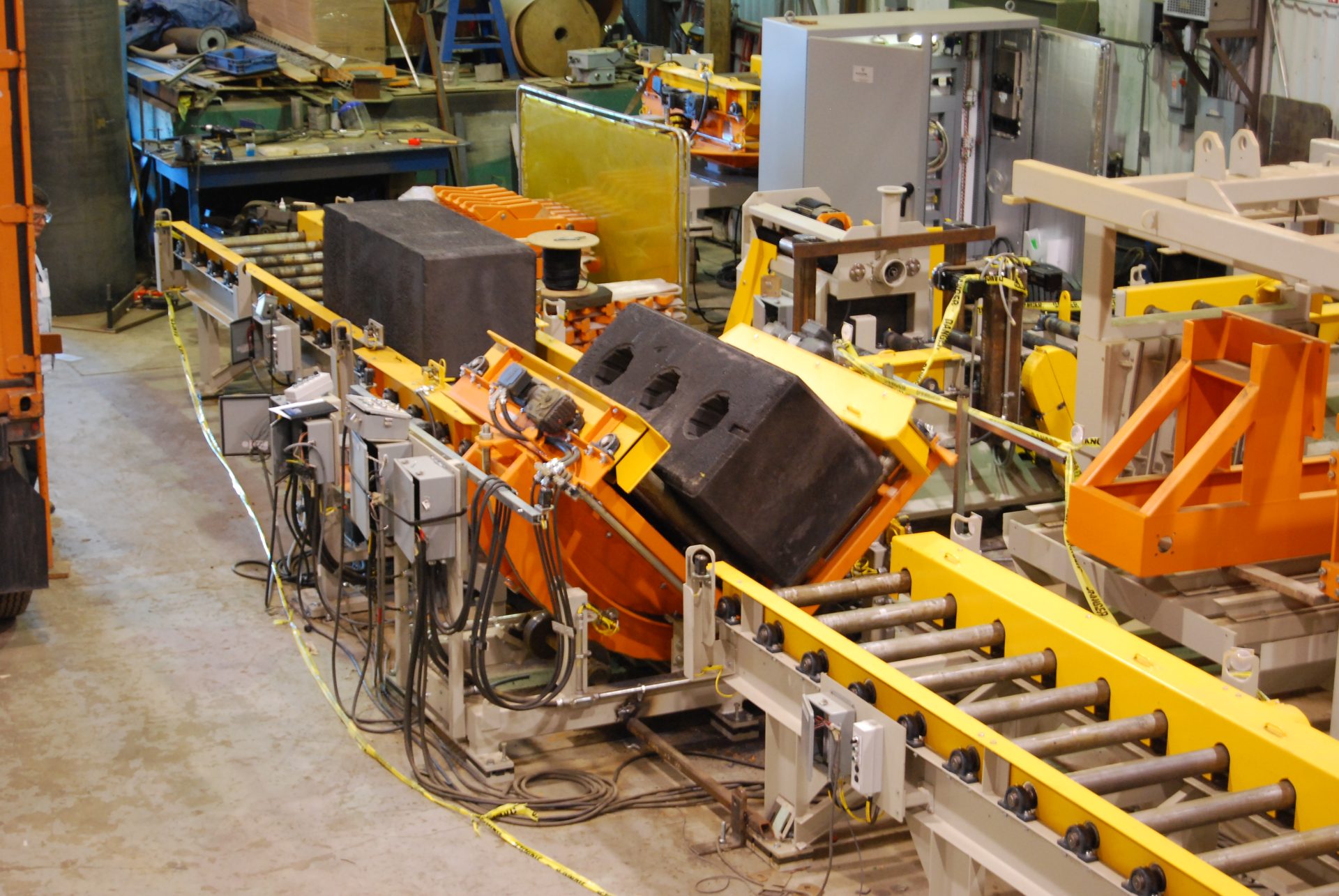

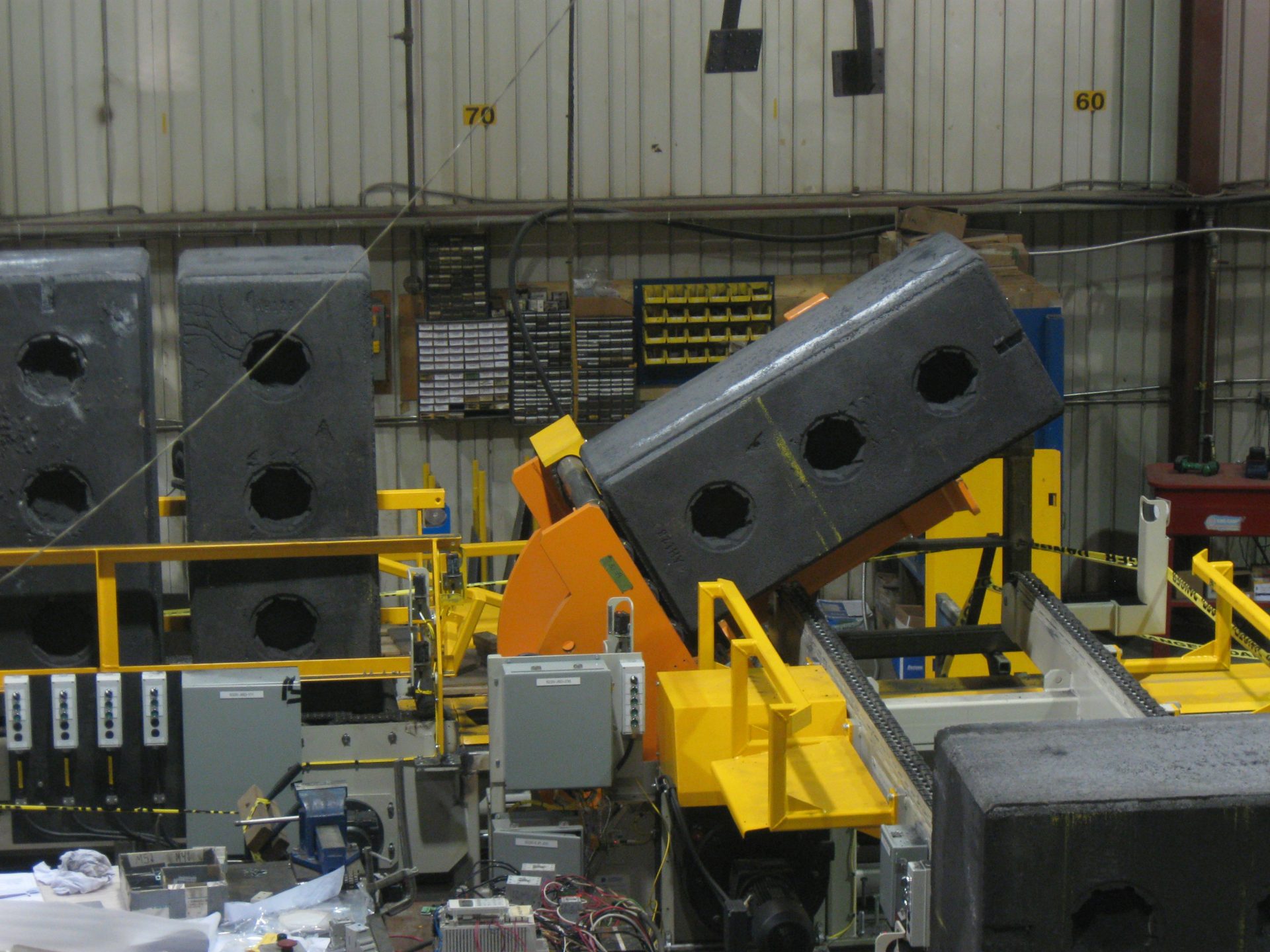

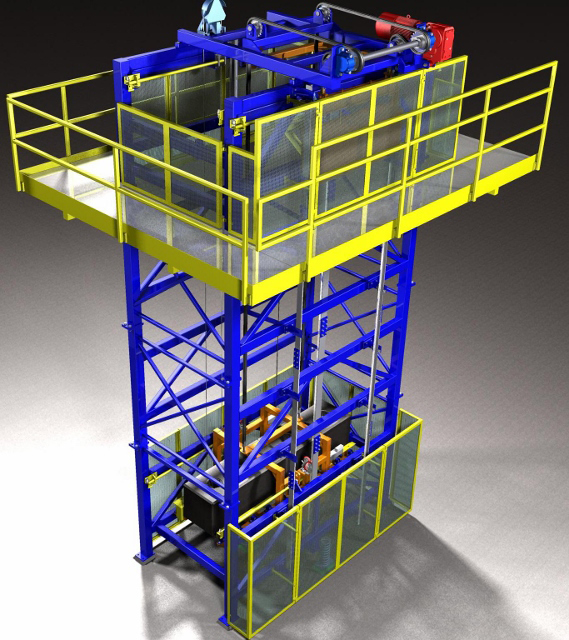

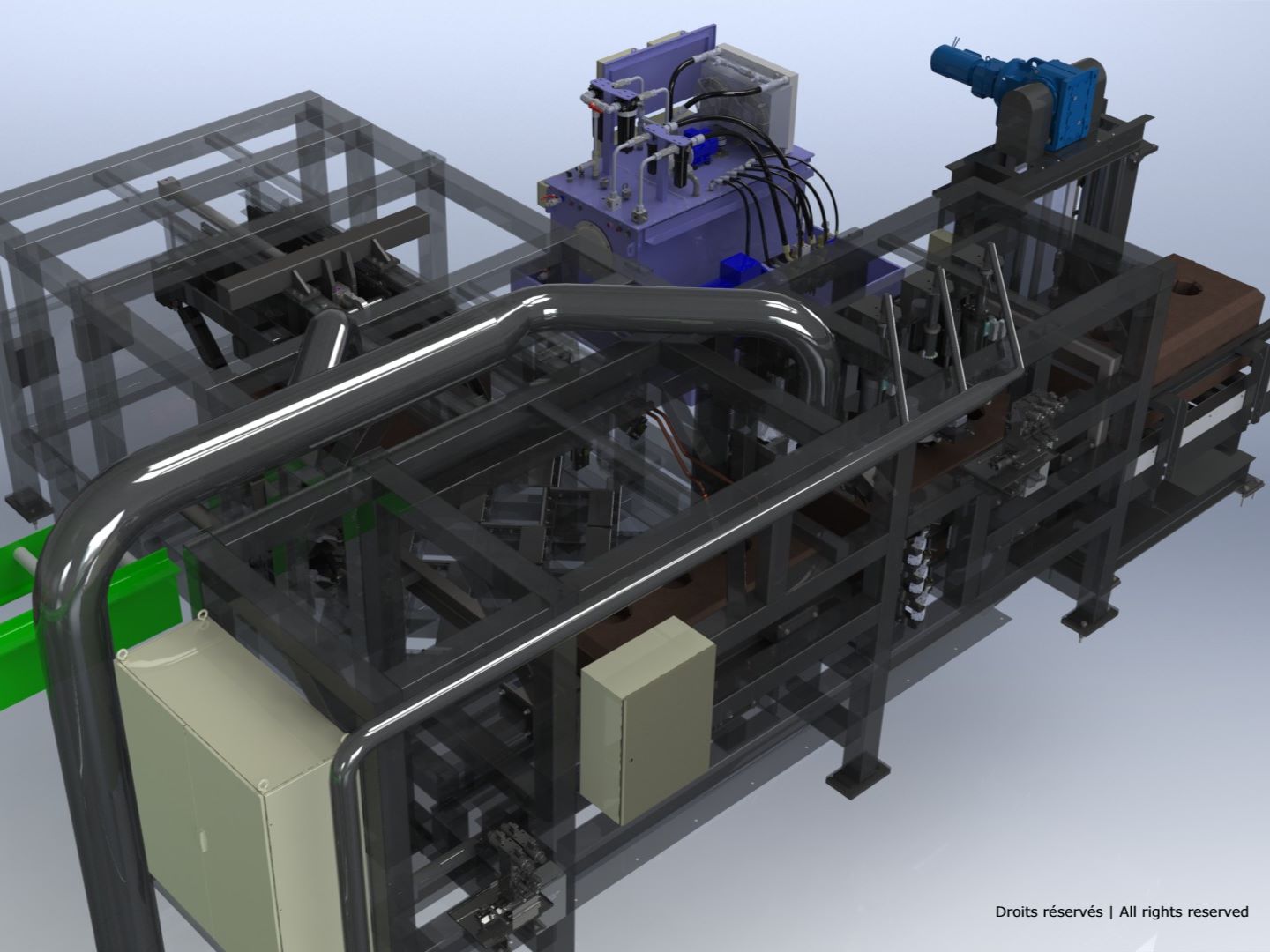

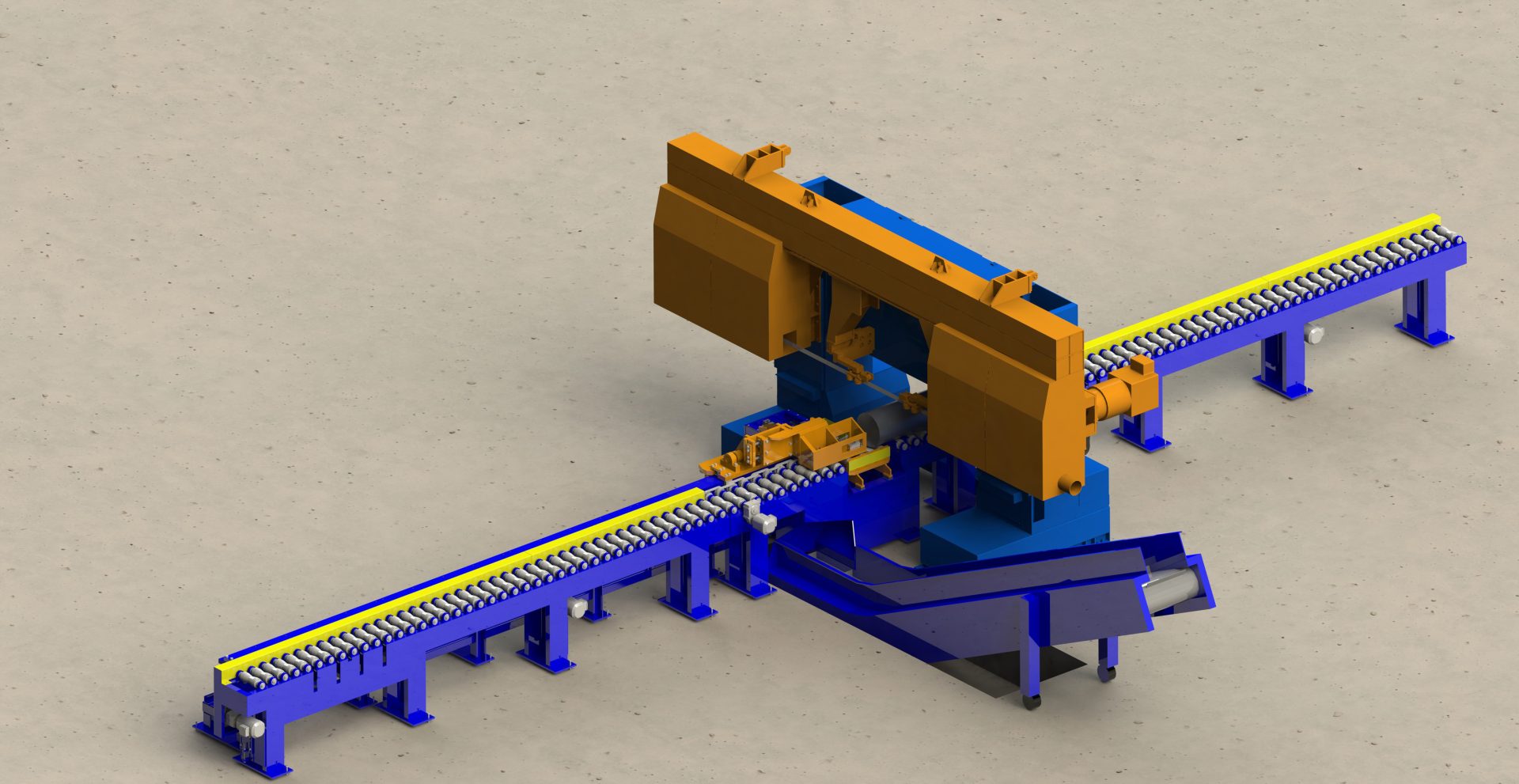

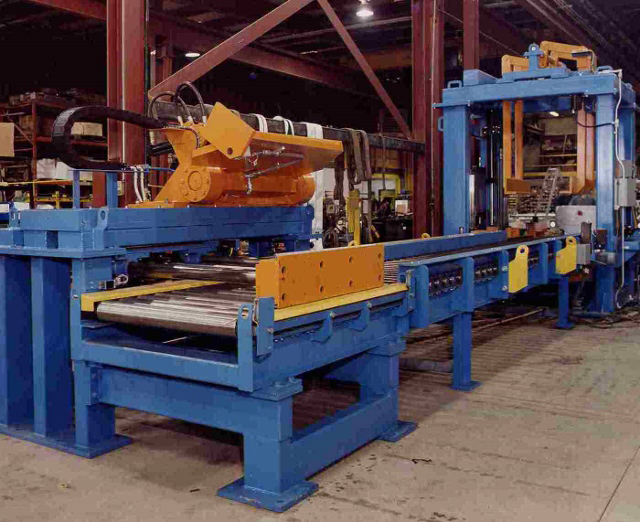

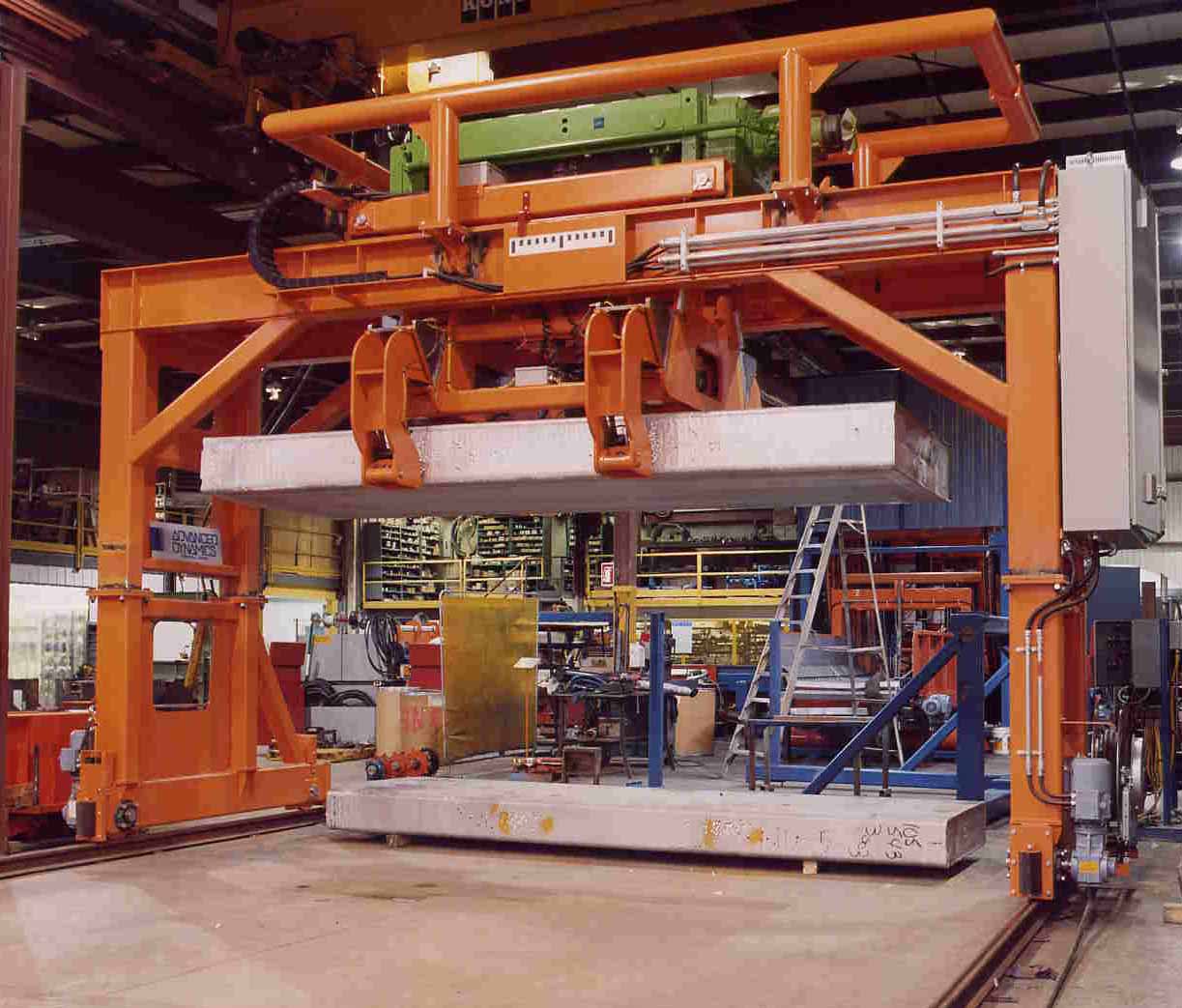

Heavy-duty Material Handling Systems

for Aluminum Casthouse and Smelters

Increase your productivity with our heavy-duty material handling, processing and packaging systems. Trust the AD equipment.

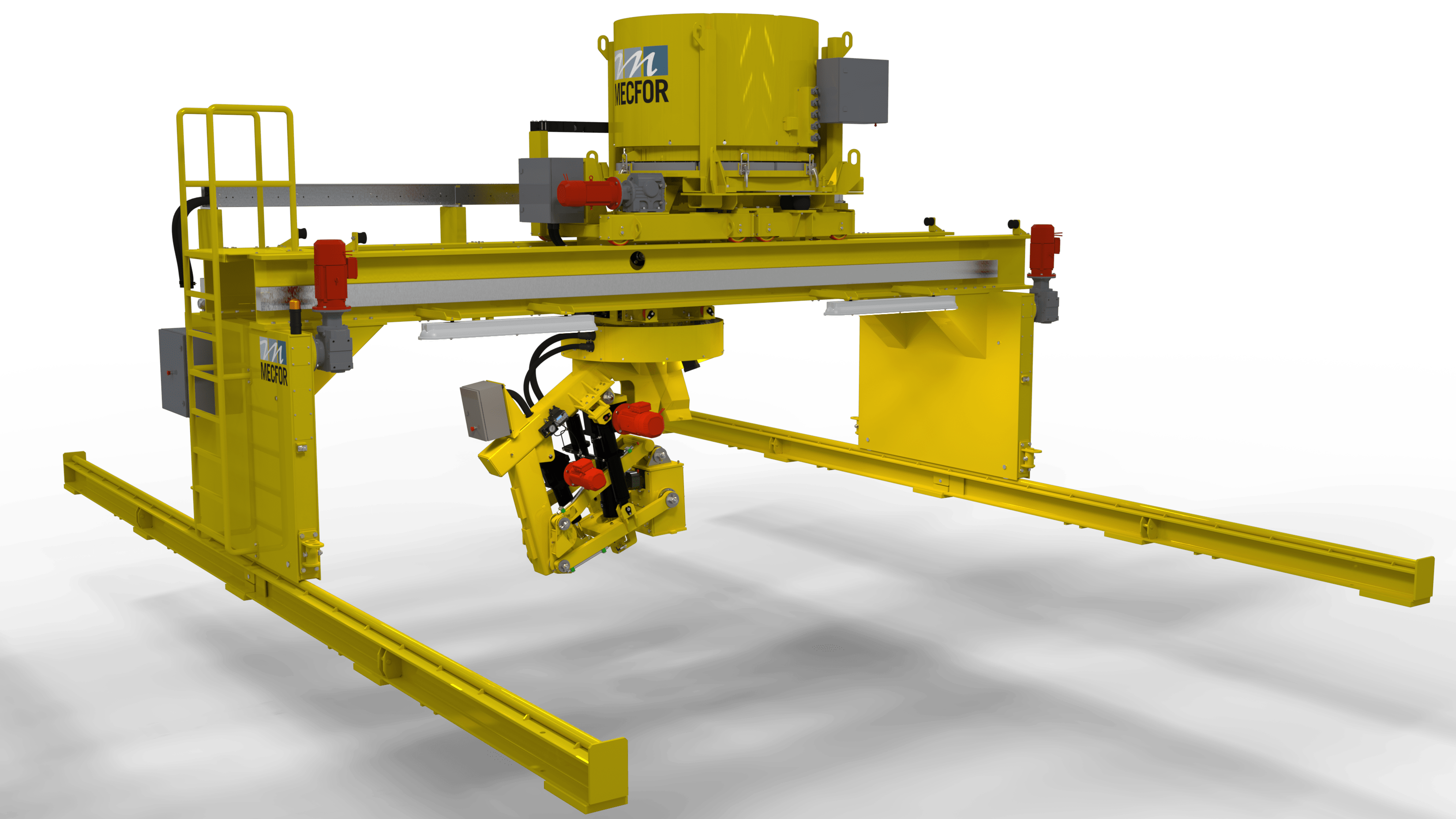

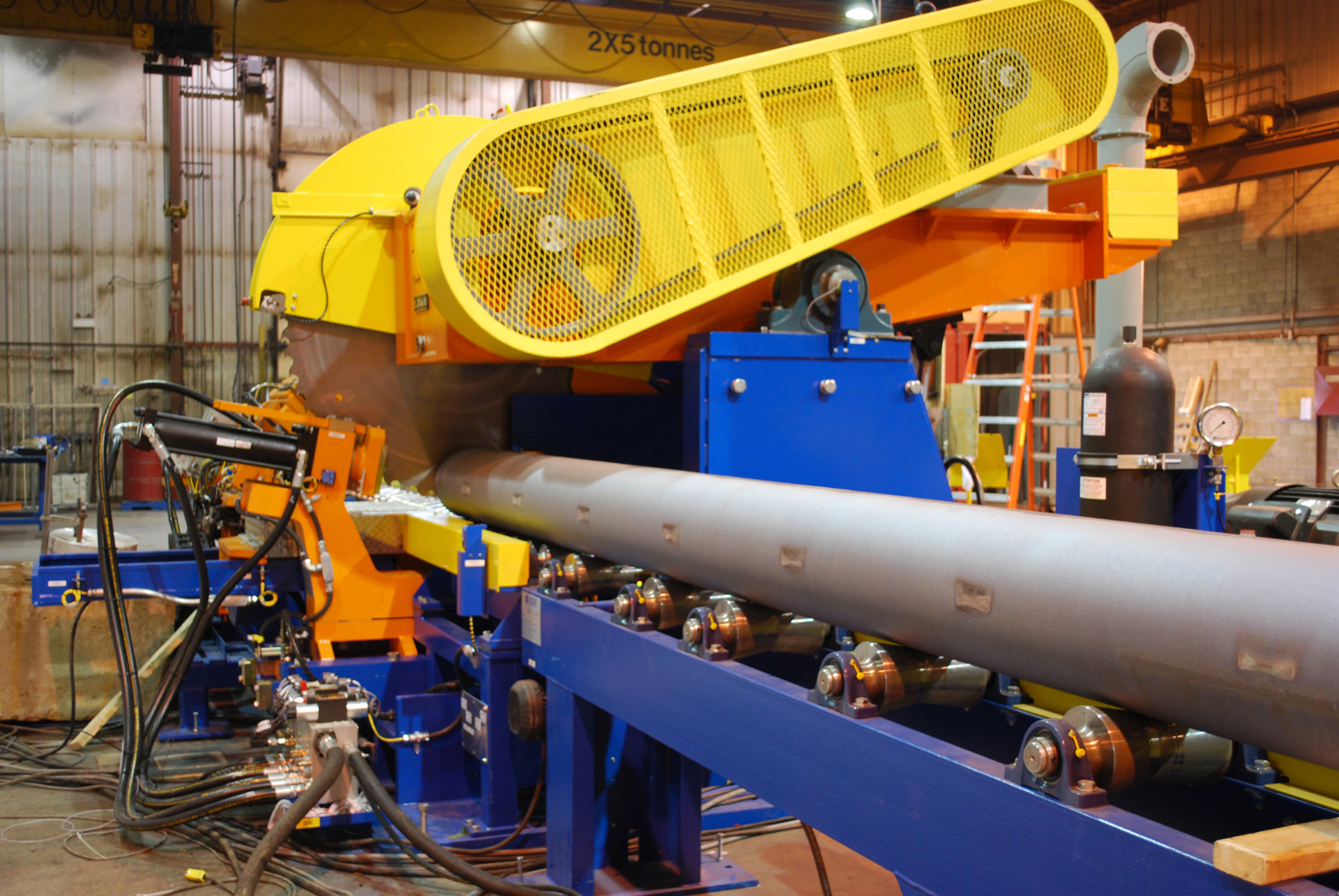

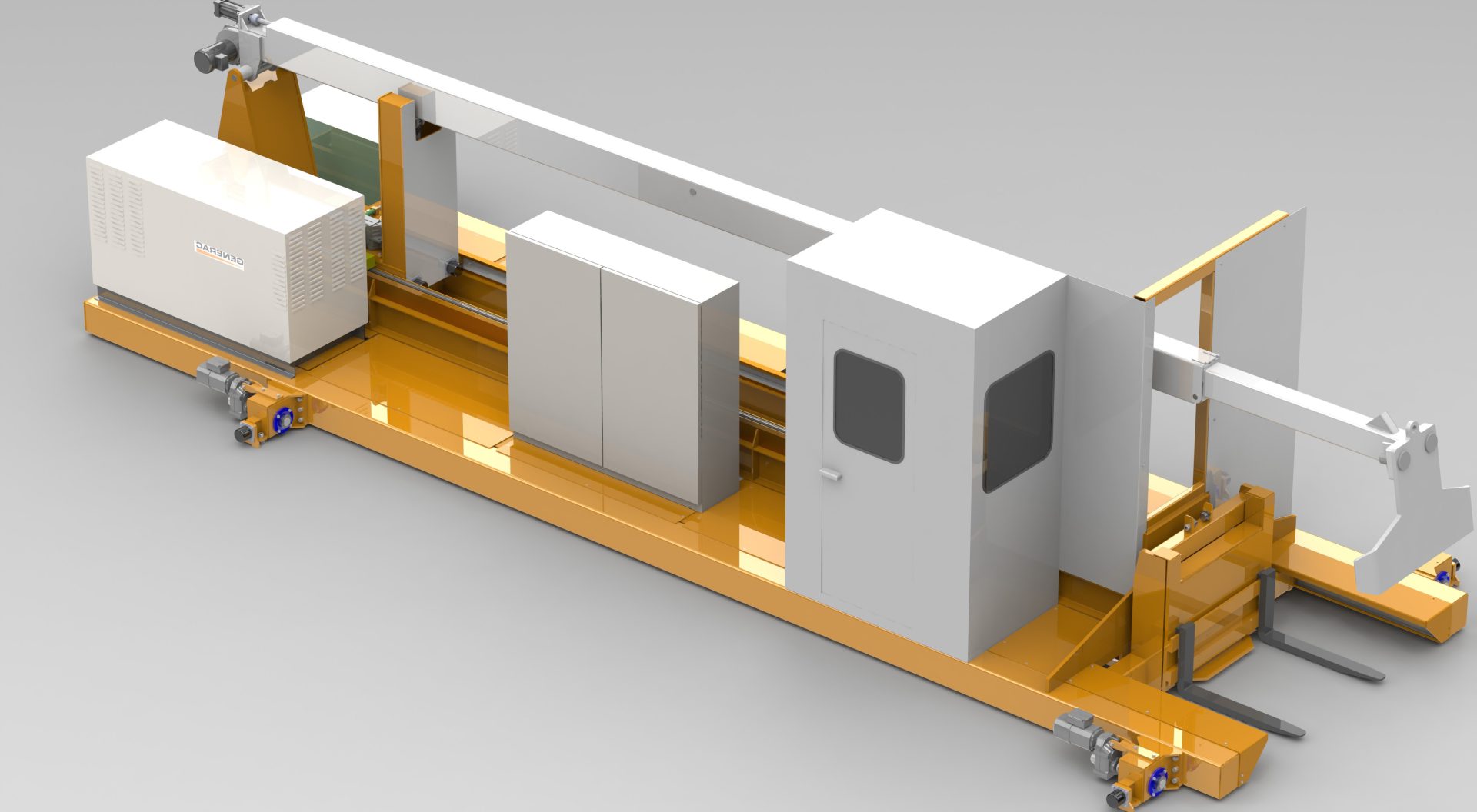

Mobile Solutions: Conventional or Custom-made

MECFOR brand is a range of mobile and custom-made equipment that can be found in all sectors of an aluminum smelter. MECFOR is synonymous with sturdy proven technology that meets demanding constraints faced by the industry.

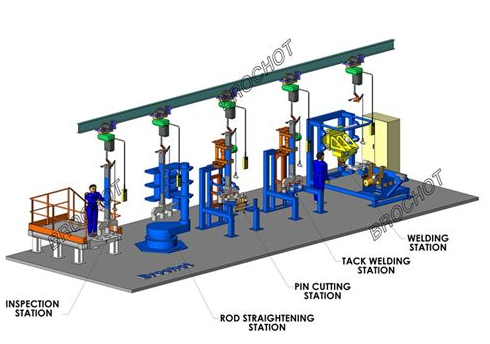

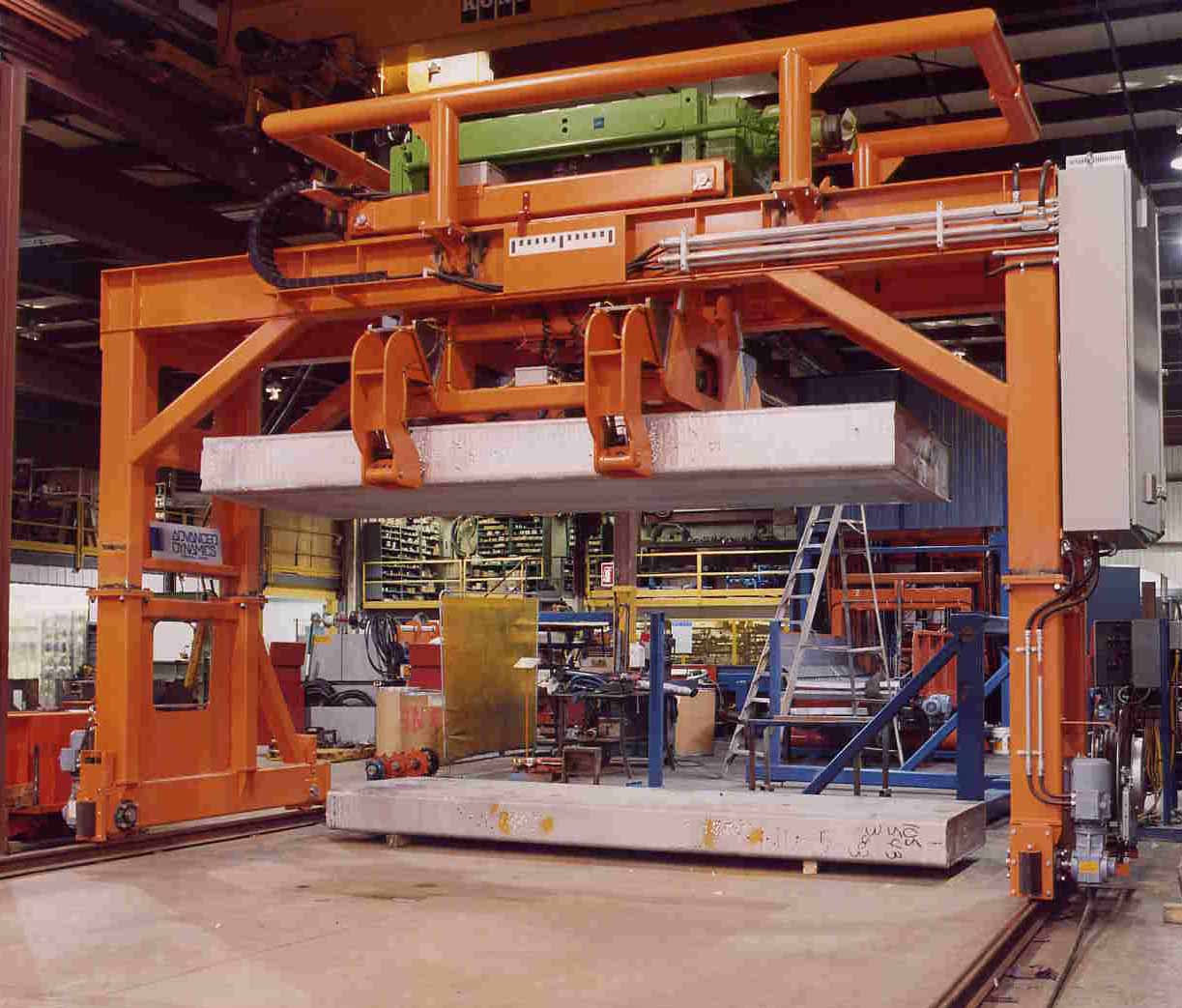

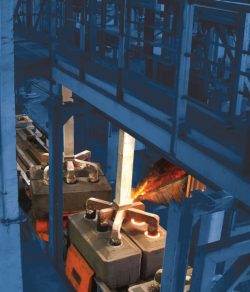

Carbon Plant and Rod Shop Equipment

BROCHOT equipment have been around the aluminum smelters for over a century; their design and innovation have carved the way Carbon plants and rodding shop are still operating today.

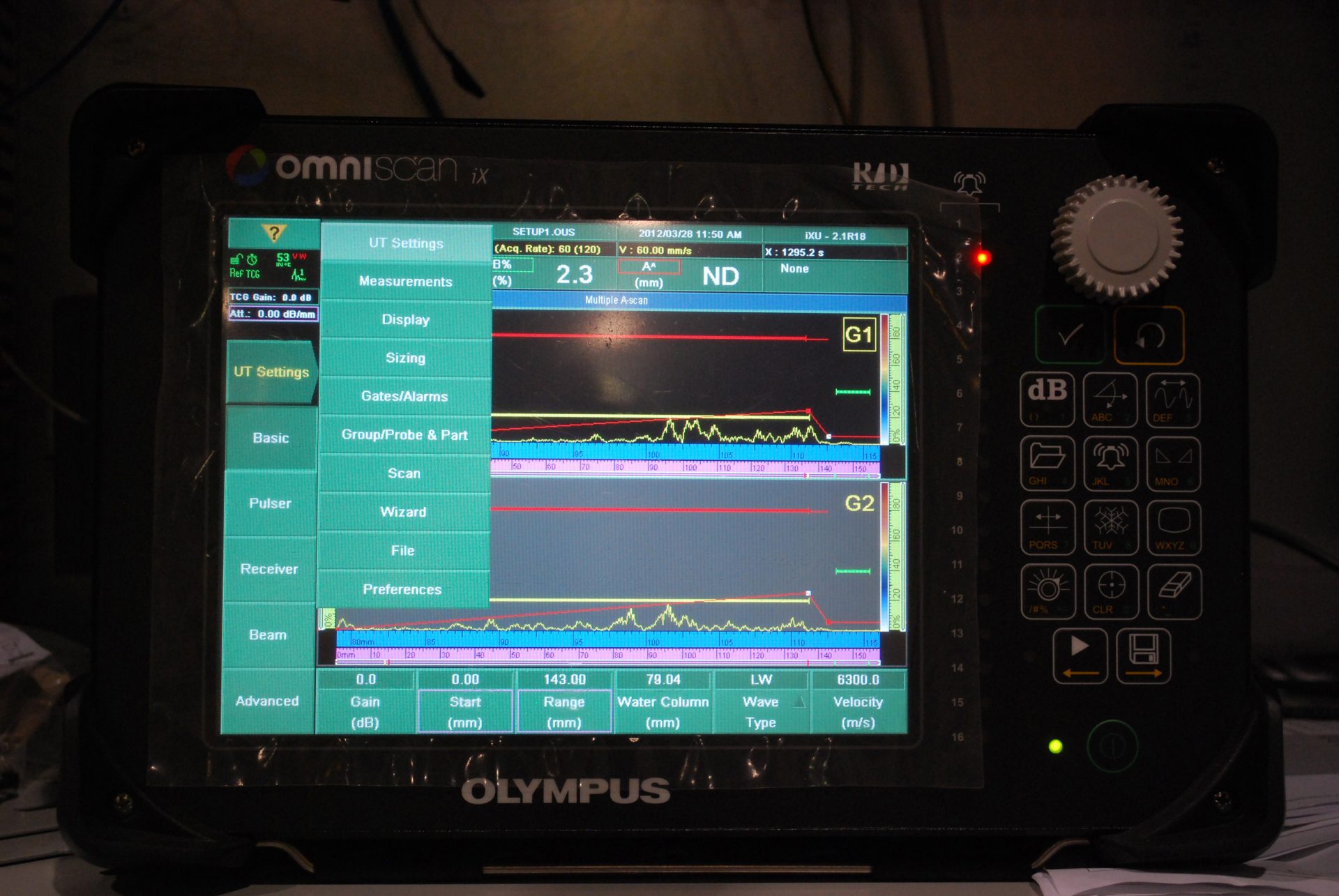

AD line of products aim to improve your productivity. The brand offers a world leading Anode Handling and Cleaning Systems. Numbers of new Industry 4.0 technologies are ready now for integration to improve product quality, reduce energy consumption, increase operator safety and ergonomics. Also, in your aluminum casthouse. Our group of highly trained engineers, designers, and project managers will help you get the most of your aluminum plant on time and within your budget.

MECFOR , our mobile equipment brand, take on your toughest challenges from stringent environment: from carbon plant to casthouse. Resisting to strong magnetic fields, carrying heavy loads of molten metal or ensuring multipurpose operations for optimal fleet management, MECFOR mobile equipment embarked most recent technologies bridging the gap between safety and efficiency.

Under the BROCHOT brand, we can deliver a complete Rodding Shop of all modern pre-bake anode technology. We offer an anode management system which coordinates communications between the various carbon plant processes and manages the anode storage facilities. In addition, get high-quality pot rebuilds using our world leading BROCHOT Pot Ramming Machine. Still today, the unique design favors an optimal compaction making sure that all joints are sealed properly.